Tailor-made

services

At SafeLi Recycling Ltd, we offer specialist technical consultancy services across the entire lithium-ion battery recycling value chain—from R&D projects to safe handling and shredding to hydrometallurgical material recovery. Our core offerings are listed below

Health & Safety in Battery Recycling

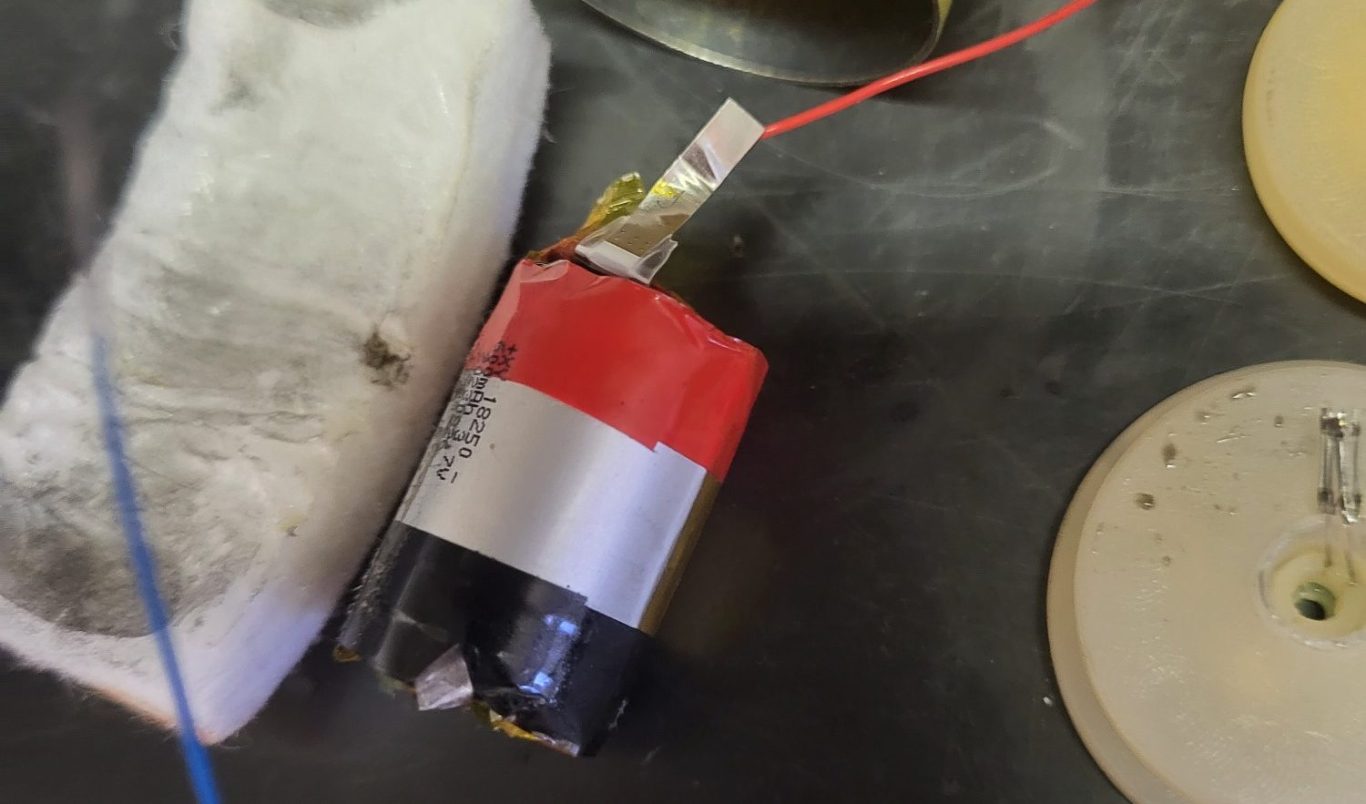

Employee safety and risk mitigation are essential in any battery recycling operation. Lithium-ion batteries present unique and serious hazards—including thermal runaway, fire, toxic chemical release, and long-term exposure risks. Black mass has even been described as “the new asbestos” and rightly demands a high level of respect in handling and processing.

We support clients with end-to-end H&S strategy, focusing on:

Fire & Explosion Prevention

Most incidents occur during storage, transport, or mechanical processing. We help you:

- Conduct detailed risk assessments

- Design and implement fire suppression and detection systems

- Develop safe storage protocols and emergency procedures

- Training of staff on recognition of different types of batteries such as primary lithium, Ni-CAD, NiMH, etc to avoid contamination

Chemical Safety

Battery components—including electrolyte, black mass, and gases and vapours—pose acute and chronic toxicity risks. We offer:

- Guidance on safe material handling and containment strategies

- Support with the appropriate LEV design and dust management

- Guidance on correct PPE for different parts of the process

- Write up of Material Safety Data Sheets (MSDS)

Whether you need a fresh risk assessment or help designing safety systems from scratch, we bring practical, science-driven expertise to safeguard your people and assets.

Lithium-Ion Battery Shredding and Black Mass Production Technologies

Battery shredding is a critical step in recycling—but it’s also one of the most dangerous if the systems are not properly engineered. We offer consultancy on:

- Optimising feedstock conditioning (sorting, chemical discharge)

- Designing inert shredding environments (e.g. water or nitrogen systems)

- Selecting the right type of shredding equipment

- Downstream separation to produce high quality black mass

- Black mass pricing and assaying

- Developing gas treatment systems for emissions control

We help you design shredding operations that are safe, scalable, and regulatory compliant

Hydrometallurgical Refining

Black mass contains valuable metals such as lithium, cobalt, nickel, and manganese, but extracting them efficiently requires strategy as well as chemistry.

We assist clients with:

- Flowsheet development, review and optimisation

- Techno-economic analysis to understand the economics of the process

- Lithium first recovery to generate lithium hydroxide without the need for a full scale hydromet plant

- Scale up from lab to pre-pilot scale

- Lithium Iron Phosphate (LFP) battery recycling

Other Offerings

We support innovation across the battery recycling value chain. If you’re developing a new process or scaling an existing one, we can assist with:

- Technical due diligence allowing you to proceed with confidence

- Process development & optimisation (lab to pilot scale)

- Market Research

- Techno-economic analysis

- Technology benchmarking

- Process development for the recycling of other types of batteries such as solid state batteries, primary lithium batteries (e.g. lithium thionyl chloride batteries)

- Authoring successful grant applications to UKRI, Innovate UK and others

From proof-of-concept to commercial readiness, we help you align your technology with real-world operational, economic, and regulatory needs.